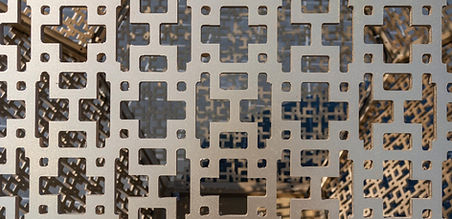

MATERIALS WE CUT

Versatile Cutting for a Wide Range of Materials

Waterjet technology allows us to cut virtually any profile in almost any material with extreme precision. Our cutting capabilities extend across a diverse range of materials, ensuring flexibility and quality for a variety of industries.

Materials we cut include, but are not limited to:

01. Metals & Alloys

Stainless steel, aluminium, titanium, brass, copper, and more. Waterjet cutting is capable of cutting a wide range of metals, including common ones such as aluminum, steel (including mild, carbon, and stainless steel), copper, brass, bronze, titanium, nickel, zinc, and magnesium. It is also effective for cutting high-performance and exotic metals like Inconel, Hastelloy, Monel, tungsten, cobalt alloys, zirconium, tantalum, niobium, and molybdenum. Additionally, superalloys and specialty metals such as chromium, tool steel (H13, D2, A2, etc.), armor plate steel, Waspaloy, and Stellite can be cut with precision. Even precious metals like gold, silver, platinum, and palladium.

.png)

02. Composites

Carbon fibre, fibreglass, and engineered composites. Waterjet cutting is well-suited for various fiber-reinforced composites, including Carbon Fiber Reinforced Polymer (CFRP), Glass Fiber Reinforced Polymer (GFRP) or fiberglass, Kevlar® (Aramid Fiber Composites), Basalt Fiber Composites, and Natural Fiber Composites such as those made from hemp, flax, and jute. Additionally, it effectively cuts polymer-based composites like epoxy-based composites, phenolic composites, polyurethane-based composites, thermoplastic composites such as PEEK, PEI, and PPS, as well as rubber composites. These materials benefit from waterjet cutting as it avoids heat damage, reduces delamination risks, and maintains structural integrity.

03. Wood & Timber

High-precision cutting for MDF wood, plywood, and hardwoods.

04. Resins, Plastics & Acrylics

Includes ABS, Acrylic and Nylon, polycarbonate, and high-density polyurethane Waterjet cutting can effectively cut a wide range of plastics, including both thermoplastics and thermosetting polymers. Thermoplastics, which soften when heated and can be reshaped, include materials such as acrylic (PMMA, Plexiglass, Lucite), polycarbonate (Lexan, Makrolon), and various types of polyethylene, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and ultra-high molecular weight polyethylene (UHMW-PE). Other thermoplastics that can be cut include polypropylene (PP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polystyrene (PS), and acrylonitrile butadiene styrene (ABS). Additionally, polyethylene terephthalate (PET, PETG), polybutylene terephthalate (PBT), nylon (PA), polyoxymethylene (POM, Delrin, Acetal), and polyphenylene sulfide (PPS) are also suitable for waterjet cutting.

05. More advanced thermoplastics

More advanced thermoplastics, such as polytetrafluoroethylene (PTFE, Teflon), polyetheretherketone (PEEK), polyimide (PI, Kapton), and polyetherimide (PEI, Ultem), can also be processed. Other plastic materials like polyurethane (PU, TPU, both rigid and flexible), ethylene vinyl acetate (EVA), polyvinylidene fluoride (PVDF), fluorinated ethylene propylene (FEP), ethylene chlorotrifluoroethylene (ECTFE), and polychlorotrifluoroethylene (PCTFE) are also effectively cut with a waterjet.

_edited.jpg)

06. Thermosetting plastics

Thermosetting plastics, which harden permanently when cured, can also be cut using waterjet technology. These include epoxy resins, phenolic resins such as Bakelite, fiberglass-reinforced plastics (FRP), melamine, urea-formaldehyde (UF), polyester resins, and vulcanized rubber, including various synthetic rubber materials.

07. Foams and specialty plastics

Foams and specialty plastics can also be cut efficiently with a waterjet. These include expanded polypropylene (EPP), expanded polystyrene (EPS, also known as Styrofoam), polyethylene foam (EPE, XLPE), polyurethane foam (PU Foam), neoprene, and silicone rubber. The versatility of waterjet cutting allows for precise and clean cutting of these materials without generating heat, which prevents melting, warping, or material degradation.

08. Silicones & Rubbers

Gaskets, seals, and other flexible components.

09. Foams, Carpet & Felts

Custom cutting for packaging, insulation, and industrial applications.

10. Laminated Dissimilar Materials

Ideal for multi-layered and mixed material components that are difficult to cut using conventional methods.

_edited.png)